Mr. Truong Anh Tuyen, Director of Tien Ngoc Company, discussed with the technical team the machine that processes waste into compost after 24 hours.

In Vietnam, waste treatment is a difficult problem.

In urban areas, landfills are overloaded, polluting the environment and becoming a nightmare for people. Many solutions have been proposed by experts but in reality, they are still not feasible. Recently, the birth of a waste processing machine into compost (organic fertilizer) designed by Vietnamese engineers has attracted the attention of the community.

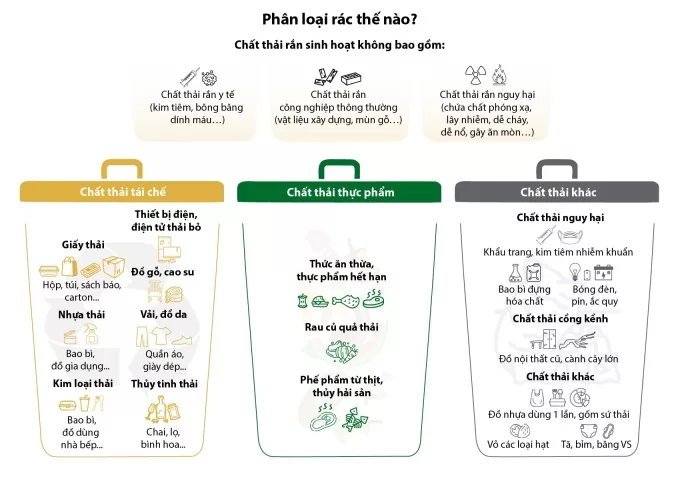

Garbage classification – A difficult problem to solve

According to researchers, the amount of solid waste in Vietnam in general and in Ho Chi Minh City in particular consists of about 64% organic waste, about 33% inorganic waste and 3% non-incinerable waste. Of which, organic solid waste is the main cause of odor pollution during the collection and transportation process and at landfills.

According to the traditional collection and treatment method, unsorted garbage is collected from households and waste sources such as markets, factories, schools, etc. and then transported to the landfill treatment plant. This method causes odor pollution and cannot be completely resolved due to the very high moisture content in organic waste. Not to mention, from the time the garbage is discharged from the source, the time between two garbage collection cycles is more than 12 hours, then from the time of collection to the time of transportation to the landfill, it takes more than 12 hours (in Ho Chi Minh City, vehicles can only enter the landfill after 9:00 p.m.). Thus, from the time the garbage leaves the source, the fastest time is 36 hours later before it is processed. During that time, due to being piled up and covered, the garbage will decompose anaerobically, creating odors and leachate. This method of collecting and treating waste has created several consequences: Pollution arising during the operation of collection vehicles, lack of space for collection sites, transfer stations, and landfills, which also takes up a lot of land….

In the world today, the waste treatment process has been standardized. Organic waste: processed by machine into compost to fertilize plants, improve soil or create dry biomass, which can be used as fuel. Compostable waste: put into an automatic gasifier, the gas produced is returned to the machine to operate the gasifier. The amount of gas and heat produced is used to generate electricity, enough to compensate for the amount of electricity needed to operate the organic waste treatment machine. The remaining non-degradable waste (about 3%) is buried.

To be able to thoroughly process waste according to this process, the key issue is still waste classification.

Waste classification at source is a program that Ho Chi Minh City has been piloting for many years, but has not yet been widely implemented and is quite an arduous journey.

As a company specializing in manufacturing and trading environmental products such as garbage bins, garbage compactors, street watering trucks, waste suction trucks… for many years, Tien Ngoc Production and Trading Company Limited is one of the units that always accompany the pilot program of waste classification at source in Ho Chi Minh City and many provinces with many specialized products such as 2-compartment and 3-compartment bins, waste classification bags for households… The company also strives to organize many training sessions on waste classification for the people, in each neighborhood and new rural areas… Mr. Truong Anh Tuyen, Director of the company, worried: “The initial waste classification pilot programs were quite effective, but then gradually decreased and then stagnated. Perhaps partly because people have not seen the practical benefits of this issue…”. Not to mention, in reality, many places encourage households to classify waste but have not implemented it synchronously, leading to the waste after being classified at households being put into containers, garbage trucks and dumped…

Waste classification at source, waste treatment on site

Not giving up, encouraging and creating consensus among people, and at the same time bringing practical benefits to each household in sorting waste at the source, finding solutions to process organic waste into compost to serve the community in fertilizing crops, building clean vegetable gardens in urban areas, since 2014 Tien Ngoc Company has successfully researched and produced compost bins supported by many localities, departments and farmers’ associations. This product has been distributed to 37 schools in Ho Chi Minh City in combination with the waste classification education program (SGGP Newspaper on May 26, 2015, published the article Taking advantage of Compost Bins). However, after a period of operation, the compost bin has revealed some limitations: decomposition time is longer than 90 days, cannot decompose hard waste, family food with a lot of meat and fish will not decompose in time, creating larvae, and leachate…

To overcome the limitations of compost bins, the company’s staff and engineers have started researching and manufacturing organic waste treatment machines that meet many criteria: Quickly process waste on-site after sorting, without creating odors and leachate. Within just 24 hours, over 80% of the waste has decomposed into steam and CO2, the rest becomes compost, which is very good for soil improvement and growing organic vegetables. After two years of research with many generations of machines, the organic waste treatment machine has now been completed and put into trial use.

The rapid organic waste treatment machine has a system that combines mechanical engineering and the operating mechanism of microorganisms, including a 2-shaft tooth grinder, a dry fuel gasifier. After being put in, organic waste will be crushed by a 2-shaft grinder into small pieces. The aerobic decomposition machine will simultaneously provide optimal conditions for temperature, humidity, and oxygen to accelerate the activity of aerobic bacteria introduced into the system, so the decomposition of organic waste occurs quickly within 24 hours, does not create leachate, the light smell of decomposing waste will be completely treated before being discharged into the environment, the decomposition process does not create larvae… The system is compact, can be equipped for places with sources of organic waste, kitchen food such as military barracks, factories, schools, hospitals, restaurants, hotels, farms… or residential areas with waste classification at source, with an organic waste capacity of 20kg/day or more. In some places, there is no need to use compost but only take biomass in the form of dry fuel, which can then be further decomposed by a gasifier, creating energy for other useful applications…

The organic waste treatment machine has brought convenience to consumers in thoroughly treating organic waste on the spot, contributing to significantly reducing the amount of waste released into the environment. Organic waste in a cycle is recycled and put into use, contributing to saving and reducing many problems such as no need for collection and vehicles, reducing traffic jams, pollution, reducing fuel consumption, human resources, and means of transporting waste from source to landfill… This is the driving force when people see the meaning of classifying and treating waste at the source, contributing to protecting the environment while improving the life and health of the community.

Currently, the organic waste treatment machine with a capacity of 20kg/day is being tested in a garden in District 2 and is showing good results. Mr. Tuyen said: “We are designing a larger machine and putting it into use in some schools, in coordination with the waste classification education program at the source. Children will be able to practice and see firsthand the effectiveness of waste classification after it is recycled and directly used as fertilizer for the school vegetable garden, serving meals right at school”.

Currently, the organic waste treatment machine at the source has been registered for copyright at the Intellectual Property Office with many types of machines. The machine can process 20 – 30kg of waste/day and 50 – 100kg of waste/day depending on the amount of waste at the place of discharge such as hospital, school, agency, factory, or market… The company is also researching and designing a waste treatment machine to serve households with a capacity of about 3 – 5kg of waste per day.

Source: Saigon Giai Phong Newspaper